A cegueira em torno das emissões de CO2

Relatórios de emissões de CO₂ geralmente são difíceis de entender. A metodologia usada para medir as emissões é complexa e, muitas vezes, vaga.

A maioria das empresas não inclui sua cadeia de suprimentos, principalmente porque ignora o que acontece nela. Por isso, acabam publicando resultados incompletos.

Decidimos realizar um estudo sobre nossas emissões de CO₂ para compreender ainda mais profundamente a realidade da VEJA.

Tentamos tornar nossos resultados acessíveis para todos, mergulhando em uma cadeia de suprimentos que já conhecemos intimamente.

Acreditamos que a única maneira de eliminar pontos cegos é calcular tudo e divulgar tudo.

Mas, afinal, o que são

as emissões de CO₂?

Nossa pegada de carbono coletiva representa a quantidade de CO₂ (dióxido de carbono) e outros gases lançados na atmosfera. Uma certa quantidade de dióxido de carbono ocorre naturalmente, mas as atividades humanas aumentaram muito esses níveis.

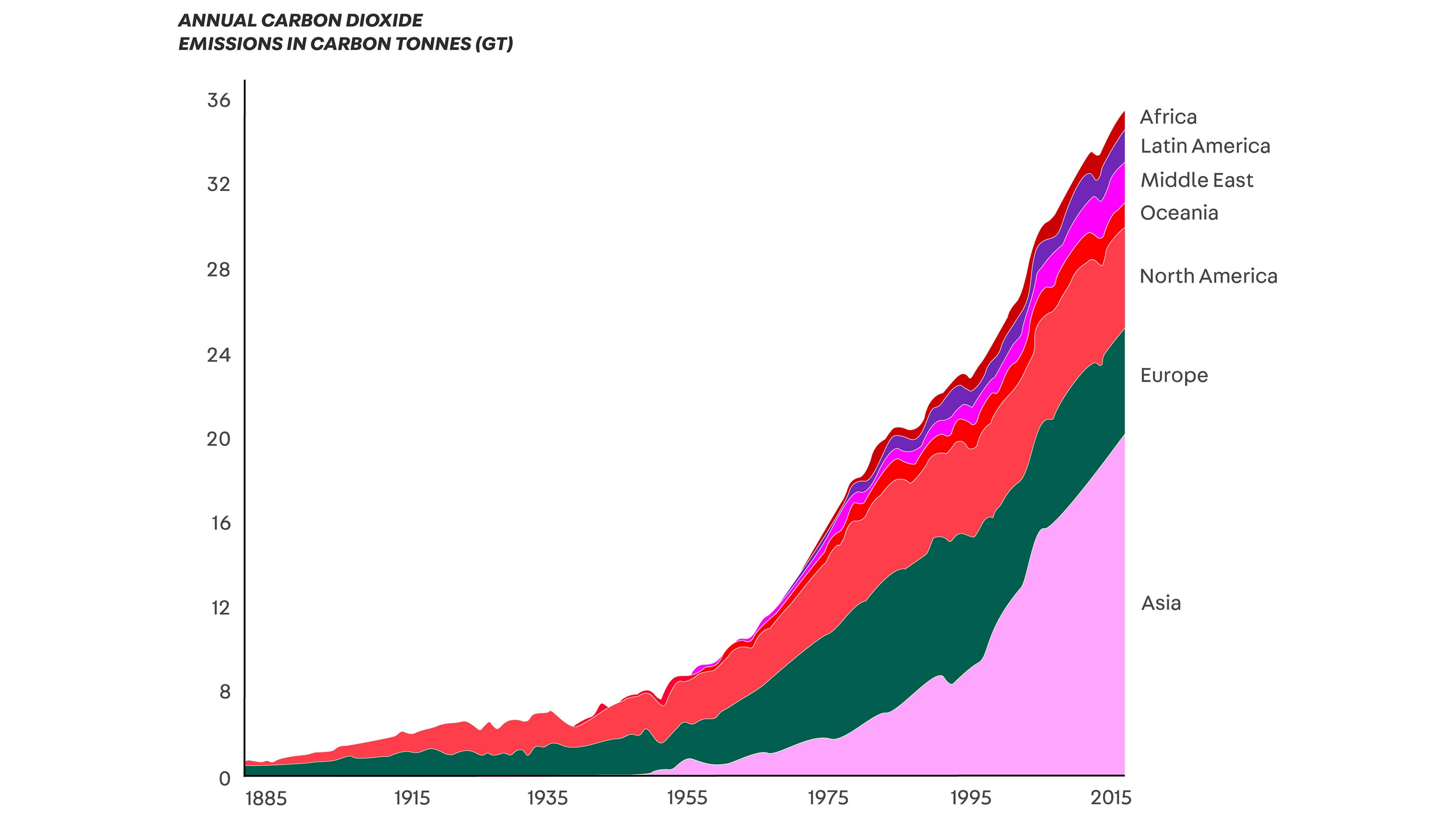

Emissões globais de CO₂ por região

© Consultancy.uk

O carbono está em todos os lugares. No ar que respiramos (e exalamos), nos alimentos que comemos e nos produtos que compramos e usamos.

1kg de CO₂ equivale ao consumo de 12kWh de eletricidade (na França).

Alguns exemplos do que é possível alimentar com 1kWh:

48 horas de uso de um laptop

Aproximadamente 3 horas com a TV ligada

1 ciclo da máquina de lavar roupas

Usar a chaleira elétrica 10 vezes

Como essas emissões

são calculadas?

Decidimos levar tudo em consideração.

Isso significa calcular muito mais do que o mínimo exigido, começando pelas matérias-primas, passando pelo transporte, fábricas de tênis e envio dos produtos.

Enquanto muitas empresas consideram apenas os Escopos 1 e 2 (as atividades mais diretas e significativas), nosso principal foco foi o Escopo 3, que engloba a produção dos tênis e as matérias-primas.

- Nordeste do Brasil e Chincha, Peru

Lona feita de algodão orgânico - Acre e Amazonas, Brasil

Solados feitos de borracha amazônica - Porto Alegre e Fortaleza, Brasil

Produtos confeccionados com dignidade - Santo André, Brasil

B-Mesh, tecido feito de 100% garrafas plásticas recicladas - França

Parte da logística da VEJA é gerenciada pela Log’ins, empresa de inclusão profissional e social

Produtor de algodão orgânico

Brasil, 2018

© VEJA

Os membros da equipe de compras levaram quase um ano para reunir todos os dados e detalhes, o que foi mais fácil para nós, já que a VEJA trabalha diretamente com produtores de borracha e algodão orgânico.

Escolhemos a agência UTOPIES para nos ajudar nesse relatório. Conhecemos a equipe há mais de 15 anos e confiamos totalmente neles, pois são uma das melhores agências francesas de sustentabilidade.

Pedimos que entregassem o estudo mais detalhado e transparente possível. A parte mais desafiadora foi reunir todas as informações logísticas.

O grande segredo das emissões de CO₂

Quando reunimos todos os dados, ficamos muito surpresos.

Escopo 1: refere-se às “atividades diretas” da empresa, que estavam próximas de zero quando calculamos nossas emissões pela primeira vez, em 2019.

Nossas emissões foram de 12,8 tCO₂e para o Escopo 1 em 2021.

Escopo 2: envolve a energia utilizada diretamente pela VEJA (eletricidade e aquecimento). Esse escopo não inclui a produção dos tênis nem as matérias-primas.

Nossas emissões foram de 3,5 tCO₂e para o Escopo 2 em 2021.

Escopo 3: é a única forma de obter uma visão completa do impacto global. Inclui todas as atividades, materiais, eletricidade e combustíveis usados nos campos, fábricas e escritórios.

Nossas emissões foram de 69.765,4 tCO₂e. para o Escopo 3 em 2021.

Os Escopos 1 e 2 representam apenas 0,03% da pegada total de carbono da VEJA.

Escopo 1

Atividades diretas da empresa, como os carros da VEJA no Brasil.

Veículos corporativos

Carro da VEJA

Brasil, 2008

@VEJA

Escopo 2

Consumo de energia em escritórios e lojas.

Eletricidade / Aquecimento

Showroom VEJA

Paris, 2019

© VEJA

Escopo 3

Todas as atividades realizadas por fornecedores e parceiros (dos campos às fábricas e escritórios):

Matérias-primas (algodão orgânico, borracha amazônica, couro e outros materiais)

Transporte (dos campos às fábricas)

Fábricas de calçados (eletricidade, combustíveis, resíduos)

Distribuição (armazéns, clientes e varejistas)

Fim de vida útil (pares coletados, reparados, reutilizados e reciclados)

Escritórios (Paris, resíduos, viagens de negócios, deslocamentos diários)

69.765,4 tCO2e em 2021

Fábrica

Brasil, 2019

@VEJA

Todos dizem: “essas não são MINHAS emissões de CO₂, mas sim as emissões de outra pessoa que faz parte do processo".

Mas, como essas pessoas não fazem parte da nossa equipe, acabamos achando que essas emissões não são responsabilidade nossa.

Escopo 2

A sede da VEJA realocou seu escritório em Paris.

O antigo escritório, localizado na Rue de Cerisaie, tinha alto consumo de gás para aquecimento (em 2019, foram 15.997 kWh em eletricidade e 122.010 kWh em aquecimento).

Deixamos claro que queríamos calcular tudo, das matérias-primas à produção, transporte e logística.

Tudo faz parte do nosso impacto. Apenas o Escopo 3 realmente importa.

Comparando as emissões dos Escopos 1 e 2 de 2019 a 2020, as emissões da VEJA diminuíram mais de 70%. Como?

Escope 1

Devido à pandemia, os funcionários usaram menos os carros da VEJA no Brasil.

No novo escritório, na Rue de Paradis, escolhemos a Enercoop para fornecer eletricidade 100% verde (foram consumidos 75.133 kWh em 2020).

Nosso consumo de eletricidade e aquecimento vem de fontes renováveis.

Então, por que as emissões de CO₂ da VEJA são altas?

As emissões de CO₂ da VEJA são altas porque consideramos absolutamente tudo.

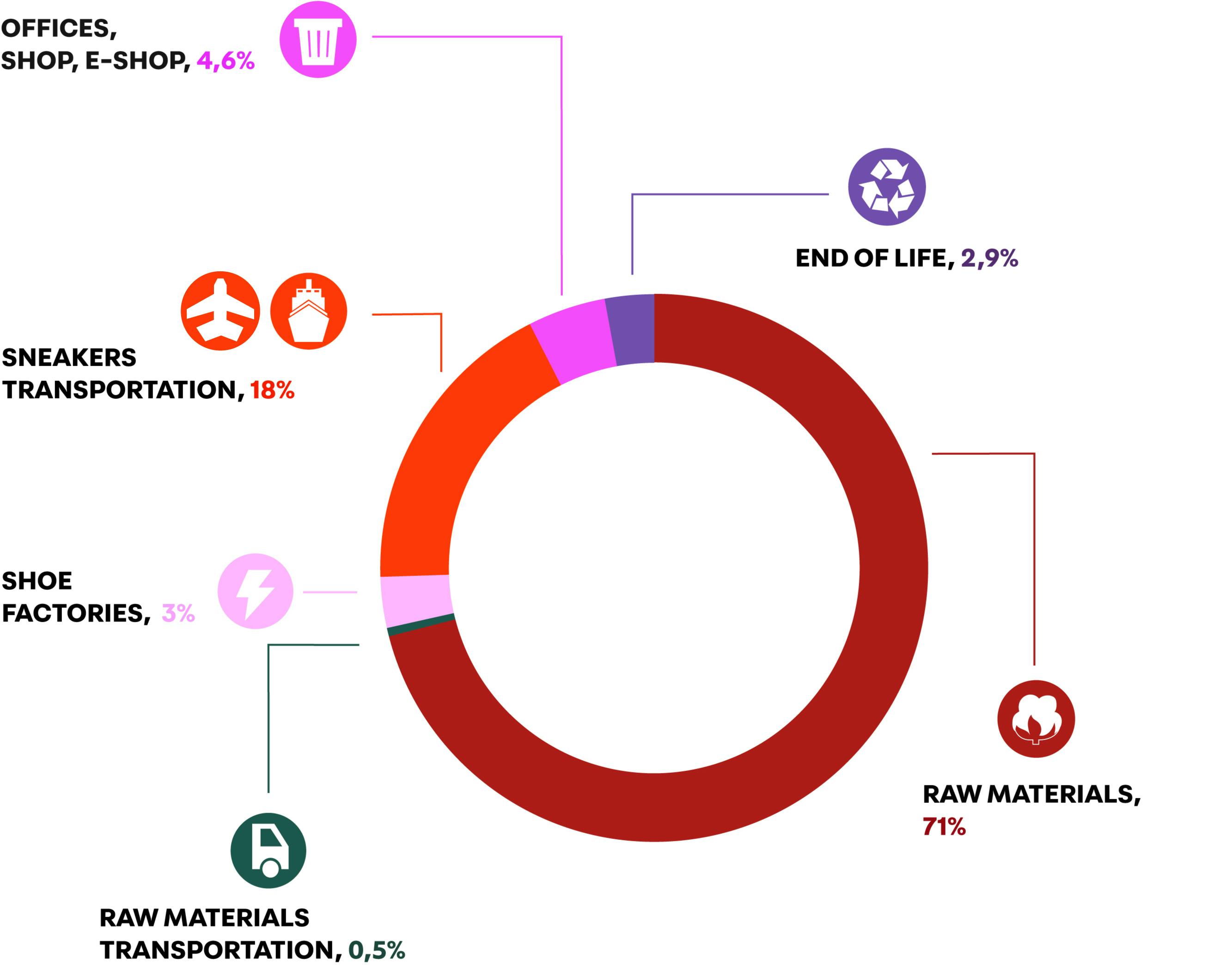

Proporção das emissões de CO₂ da VEJA em 2019

ESCRITÓRIOS / LOJAS / E-SHOP EM 2021, 4,6%

Todas as atividades relacionadas a escritórios e lojas: resíduos, compras, instalações, veículos, eletricidade, viagens da equipe, deslocamentos, aquecimento a gás e serviços postais.

TRANSPORTE DOS TÊNIS EM 2021, 12,8%

Distribuição do Brasil para nossos armazéns, clientes e varejistas.

FÁBRICAS DE CALÇADOS EM 2021, 2,5%

Eletricidade, combustíveis e resíduos gerados nas fábricas.

TRANSPORTE DAS MATÉRIAS-PRIMAS EM 2021, 0,5%

Frete das matérias-primas, desde os campos até as fábricas de calçados.

MATÉRIAS-PRIMAS EM 2021, 79,3%

Todas as matérias-primas usadas na produção: couro, algodão orgânico e borracha amazônica.

Inclui também a energia usada no processamento e os resíduos gerados durante a fabricação.

FIM DE VIDA ÚTIL EM 2021 3,3%

Embalagens dos calçados e estimativa de pares coletados, reparados, reutilizados e reciclados.

Quais emissões

por modelos?

© VEJA

Um modelo de couro emite quatro vezes mais CO₂ do que um modelo de algodão orgânico.

Percebemos que o couro tem um papel importante em nosso estudo.

O impacto do couro

79,3% das emissões de CO₂ da VEJA são geradas pelas matérias-primas: algodão orgânico, borracha amazônica, couro e materiais inovadores como B-Mesh, Hexamesh e Alveomesh. Dessas emissões, 97,43% são causadas pelo couro.

Consideramos o impacto desde os produtores das fazendas até o curtume.

Conseguimos rastrear nosso couro desde os fazendeiros diretos até o abatedouro, mas não os indiretos.

Os fazendeiros indiretos são aqueles que criam os bezerros e os enviam para os fazendeiros diretos com quem trabalhamos, que os criam para a produção de gado.

Fábrica de couro

Brazil, 2018

© VEJA

Gado

Brasil

© VEJA

O couro usado na produção dos nossos tênis vem de fazendas do Sul do Brasil e não provém de áreas em processo de desmatamento.

Mesmo que usar couro nem sempre seja a melhor opção, ele nos permite produzir tênis duráveis.

Como os animais são criados e vendidos pela carne e não pela pele, o couro é considerado um subproduto. Nós damos valor a esse couro e o utilizamos em seguida.

Em média, 70% da pegada de carbono do couro ocorre durante a criação do gado (principalmente devido ao processo natural de digestão do animal).

Os 30% restantes são referentes à produção do couro, curtimento e transporte.

Desde 2008, a VEJA trabalha para melhorar a cadeia de produção do couro, com foco em rastreabilidade e transparência química.

Proporção de couro usado

nas coleções da VEJA

Todos os nossos couros não contêm substâncias químicas perigosas ou proibidas.

Usamos couro ChromeFree em todas as linhas infantis e em modelos selecionados da coleção adulta.

© Vincent Desailly

Após anos de pesquisa, começamos a trabalhar com alternativas ao couro mais ecológicas do que o plástico.

Em 2019, lançamos nosso primeiro modelo feito de C.W.L, uma alternativa vegana ao couro, produzida com lona de algodão orgânico revestida com amido de milho e óleo de mamona.

Também transformamos garrafas plásticas em materiais alternativos, dando um novo destino ao lixo.

O B-mesh é um tecido totalmente feito de poliéster reciclado, e Hexamesh é composto por 70% algodão orgânico e 30% garrafas plásticas recicladas.

Nosso couro passa por um processo de curtimento inovador, sem uso de cromo, metais pesados ou ácidos perigosos.

Nosso processo de curtimento consome menos energia, reduz o uso de água em até 40% e de sal em 80%.

Além disso, a água utilizada continua reciclável.

© VEJA

Garrafas plásticas antes da transformação

2014

© VEJA

O impacto do algodão orgânico e da borracha amazônica

O cultivo, a coleta e a transformação do nosso algodão orgânico e da borracha amazônica representam 0,5% das nossas emissões de matérias-primas.

Extração da borracha amazônica

Brazil, 2016

© VEJA

O algodão orgânico e a borracha amazônica são alguns dos principais materiais dos nossos tênis.

Compramos mais de 4.000 toneladas de borracha amazônica e 1.843 toneladas de algodão orgânico de 2004 até o final de 2024.

Como trabalhamos todos os dias com famílias de produtores, conhecemos nosso impacto nos campos.

Os benefícios de obter matérias-primas diretamente do campo

Comprar borracha amazônica de seringueiros aumenta o valor econômico da floresta e das famílias que a protegem. Eles ganham mais dinheiro extraindo borracha do que criando gado, ajudando a combater o desmatamento.

A VEJA produziu, em 2021, cada sola com 20 a 40% de borracha da floresta amazônica.

Solas de borracha amazônica

Brasil, 2019

@VEJA

Mesmo com o aumento da produção, economizamos até 29 toneladas de CO2e apenas aumentando o uso de borracha amazônica.

O impacto da borracha amazônica é de 0,67 tCO2e por tonelada (produção e logística), comparado a 2,49 tCO2e por tonelada para a Borracha Estireno-Butadieno (SBR), um tipo de borracha sintética.

A borracha amazônica emite cerca de 73% menos gases de efeito estufa do que a borracha convencional usada na indústria.

A prática da agroecologia no algodão orgânico usado em nossos tênis ajuda na absorção de carbono.

Ela também fertiliza o solo e otimiza o ciclo da água sem o uso de pesticidas ou produtos químicos. Mais especificamente, a VEJA utiliza agricultura regenerativa.

Algodão

Brasil, 2018

@Melanie Bahuon

O algodão é orgânico, mas a forma como é cultivado vai ainda mais além: é colhido no mesmo campo que culturas de subsistência como milho, gergelim ou feijão. Isso permite que os produtores tenham independência alimentar enquanto enriquecem o solo.

Embora esses métodos agrícolas possam compensar nosso impacto de CO2, eles não foram incluídos neste primeiro estudo.

Todas as nossas matérias-primas vêm do Brasil e do Peru. Elas são transportadas de caminhão e navio diretamente dos campos para nossas diferentes fábricas nos dois países. Dessa forma, garantimos a redução do impacto do transporte transatlântico.

Transporte por navio

ou avião?

Em 2019, 81% do transporte da VEJA era feito por mar e apenas 19% por avião. No entanto, percebemos que esses 19% representavam 95% das nossas emissões de CO2 da distribuição.

Devido a atrasos ocasionais na produção, o transporte aéreo foi utilizado para enviar cerca de 19% do volume de pares.

Percebendo isso, agimos em 2020 para reduzir essas emissões: apenas 7% do transporte da VEJA passou a ser feito por avião.

Nossos maiores varejistas ainda pedem que nossos pares sejam priorizados e enviados por avião. Após este estudo, nosso objetivo em 2021 é proibir o uso de frete aéreo para enviar nossos pares do Brasil aos varejistas.

Optamos por reduzir o transporte aéreo das fábricas para os varejistas e priorizar navios de carga.

Distribuição por avião, 2019

Distribuição por navio

Distribuição por avião

Distribuição da VEJA / Emissões de CO2 geradas pela distribuição

A pegada de carbono

das equipes

Para nós, a mudança precisava começar com nossas práticas diárias nos escritórios.

Coletamos os dados de todos os membros da equipe e funcionários da VEJA sobre viagens realizadas ao longo do ano.

Para reduzir essa porcentagem, quando a viagem é necessária para conferências ou feiras, usamos o trem como principal meio de transporte se a viagem durar menos de seis horas.

Como nossos escritórios estão em Paris, Brasil e Nova York, nossas equipes utilizam transporte público, bicicletas ou até vêm a pé aos escritórios, o que é mais conveniente em grandes cidades.

No Brasil, usamos dois carros, já que algumas de nossas fábricas e campos só são acessíveis de veículo.

Parte da equipe VEJA

Peru, 2019

© VEJA

Coletar, reparar, reciclar

Caixa de reciclagem na VEJA x Darwin

Bordeaux, 2020

© VEJA

O fim de vida dos nossos tênis gera 3,3% das nossas emissões. Mesmo que essas emissões não sejam altas, sempre foi uma das nossas maiores preocupações.

Em junho de 2020, lançamos nosso novo projeto VEJA x Darwin, um hub de testes para limpar, reparar e reciclar tênis antigos.

O projeto reúne protótipos da VEJA nunca lançados, tênis com defeitos mínimos e alguns pares de coleções antigas.

Nosso sapateiro repara e limpa os tênis usados, enquanto os que estiverem em pior estado serão coletados e reciclados.

Para nós, os tênis mais sustentáveis são aqueles que você está usando.

Mesmo que sejam de outra marca.

VEJA x Darwin

Bordeaux, 2020

© VEJA

Resultados ausentes

Neste estudo, não conseguimos incluir:

O lixo produzido pelas lojas e armazéns com os quais trabalhamos.

A mobília nos diferentes escritórios.

A cadeia de entrega dos varejistas até os clientes finais.

Materiais auxiliares incluídos em nossas palmilhas, solas ou nas línguas dos sapatos.

Nossos ilhós, pois são feitos de metal que não foi obtido diretamente por nós.

© VEJA

Como reduzimos nossas

emissões de CO₂

Aumentar a proporção de couro mais ecológico

O couro ChromeFree que usamos nos modelos Campo representava 8,55% da linha adulta em 2019.

Representou 19% em 2020 e 45% em 2021.

Na linha infantil, o couro ecológico já é usado em 100% dos modelos.

Campo Chromefree White Kaki

Lookbook AW19

© VEJA

Nosso objetivo é expandir o uso do couro ecológico em todas as nossas coleções, com a rastreabilidade que nos permite afirmar que esse couro emite significativamente menos CO₂ do que o couro convencional.

Para produzir esse material, usamos 35% menos energia e 40% menos água durante o processo de curtimento em comparação com um tênis de couro comum.

Reduzir a presença de couro em nossa coleção

Para a coleção AW20, os modelos de couro representaram 51% de toda a nossa produção.

Proporção dos materiais na produção da VEJA

Usar fibras recicladas

Também utilizamos fibras recicladas, como o B-mesh.

Feito com 100% de poliéster reciclado, são necessárias três garrafas plásticas para fabricar um par de tênis VEJA.

Ao produzir um modelo V-10 B-mesh, as emissões liberadas são de 16,60 kgCO₂e, enquanto um modelo Esplar de couro integral emite 21,5 kgCO₂e.

Escolher energia limpa

95%* dos 190.180 kWh consumidos pela VEJA em 2020 vieram de fontes renováveis.

163.499 kWh correspondem ao consumo de nossos dois escritórios e quatro lojas em Paris, que recebem energia elétrica da Enercoop, uma cooperativa que produz 100% de energia renovável na França.

A Enercoop garante eletricidade 100% renovável (proveniente de água, vento, sol e biomassa) e 0% de origem nuclear, graças ao fornecimento direto de mais de 300 produtores em toda a França.

Paradis

Paris, 2019

© VEJA

Em 2025, a equipe da VEJA na França conta com 314 funcionários.

A VEJA possui duas lojas na França:

A primeira está localizada na Rue de Poitou, com 90 m² e a segunda, VEJA x Darwin, fica em Bordéus, com 350 m².

Também consideramos as lojas Centre Commercial, localizadas na Rue de Marseille (200 m²), Rue Madame (loja adulta, 140 m²) e a loja infantil com 160 m².

VEJA Rue de Poitou

Paris, 2019

@VEJA

Rue de Turenne

Paris, 2019

@VEJA

Loja VEJA

Flagship store VEJA New York, 2020

© VEJA

Em 2020, a VEJA abriu sua primeira loja nos Estados Unidos.

No primeiro ano, o consumo de energia foi de 17.532 kWh, fornecidos pela Abest, que abastece nosso escritório e loja em Nova York com 100% de energia eólica renovável.

A Abest obtém sua eletricidade limpa e eficiente de parques eólicos espalhados pelos Estados Unidos.

Em 2021, a equipe da VEJA em Nova York contava com 13 pessoas.

Temos um escritório de 204 m² e uma loja localizada em NoLita com 74 m².

VEJA offices

Brasil, 2018

@VEJA

A VEJA também possui dois escritórios no Brasil.

O primeiro, no sul do país, coordena a produção dos tênis.

O segundo, no Acre, onde nossa equipe gerencia a cadeia de fornecimento da borracha amazônica.

Juntos, em 2020, esses dois escritórios consumiram 9.199 kWh.

No Brasil, 65% da eletricidade é produzida por hidrelétricas, 8,4% por biomassa, 8,6% por vento, 1% por energia solar e 9,3% por gás natural.

Portanto, 83% da eletricidade no Brasil vem de fontes renováveis.

No entanto, apenas grandes consumidores com alta demanda de energia podem escolher seu fornecedor.

Pequenos consumidores, como a VEJA, precisam usar a eletricidade fornecida por distribuidoras locais regulamentadas.

A equipe da VEJA no Brasil, em 2025, conta com 117 funcionários.

Nosso escritório em Campo Bom (RS) tem 500 m², incluindo o centro de distribuição da VERT.

*O consumo de eletricidade dos escritórios no Brasil não foi considerado renovável, pois 17% vem de fontes não renováveis.

Se considerarmos o total de energia renovável usada pela VEJA, 99,2% do consumo total de eletricidade da VEJA vem de fontes renováveis.

Parar de enviar por avião

No entanto, esses 19% representavam 95% das emissões de CO₂ da nossa distribuição. O transporte aéreo é aproximadamente 100 vezes mais poluente do que o transporte marítimo.

Em 2020, apenas 7% do nosso transporte foi feito por avião.

Após este estudo, nosso objetivo em 2021 passou a ser proibir o uso de transporte aéreo para enviar nossos pares do Brasil para os varejistas.

Essa iniciativa nos ajudará a reduzir em 92% as emissões de CO₂ do transporte.

Em 2019, já sabíamos que poderíamos reduzir as emissões do fim de vida dos produtos em 40% oferecendo aos clientes a possibilidade de devolver seus pares usados. O fim de vida dos tênis VEJA era responsável por 1.009 tCO₂e. Se a VEJA tivesse introduzido um programa de devolução, as emissões teriam sido de 600 tCO₂e.

Porto de Santos

Santos, 2019

© Unsplash

Reparo de um tênis VEJA

Darwin, Bordeaux, 2020

© VEJA

Reciclar nossos calçados

Agora, conseguimos evitar essas emissões. Começamos com o projeto VEJA x Darwin em junho de 2020 e hoje coletamos tênis usados para serem limpos, reparados ou reciclados em nossas lojas de Paris, Bordéus e Nova York.

O carbono é apenas um dos tipos de dados usados para medir o impacto e o valor da natureza.

Existem muitas outras formas de fazê-lo, como por exemplo: biodiversidade, disponibilidade de água, ou até beleza cênica e legado.

A borracha e a agricultura regenerativa são mais do que carbono

Esses serviços ecossistêmicos ainda estão em uma fase inicial de compreensão.

Antes mesmo que sejam totalmente entendidos, nós já estamos trabalhando neles.

O algodão agroecológico, que regenera o solo, e a borracha nativa, que protege a Amazônia, são práticas que oferecem muito mais do que apenas captura de carbono.

Embora ainda estejamos medindo esses impactos, sentimos que não precisamos de dados para saber que devemos continuar avançando.

Algodão orgânico durante a colheita

Peru, Chincha

© VEJA